Accelerated Cast Iron and Bare Steel Replacement Programs

New Hampshire’s aged infrastructure contains a limited amount of aged, worn and leak-prone pipelines comprised primarily of bare steel and cast iron. In 1990, when the New Hampshire Public Utilities Commission recognized that leak-prone pipes required formal, systematic replacement, the Commission ordered an accelerated bare steel replacement program for one of our gas operators. Since that time the Commission has undertaken numerous safety related directives in many proceedings involving jurisdictional gas utilities containing cast iron and/or bare steel.

See Commission Orders Nos. 22,386 (1996); 23,333 (1999); 23,470 (2000); 24,777 (2007); 24,906 (2008); 24,996 (2009); 25,127 (2010); 25,244 (2011); 25,370 (2012); 25,378 (2012); 25,530 (2013); 25,684 (2014); 25,798 (2015); 25,918 (2016), 26,036 (2017), 26,154 (2018), 26,266 (2019) and 26,374 (2020). All Commission Orders are available for review and located on the Commission website.

In 1994, 353 miles, or 27% of New Hampshire’s distribution pipelines contained cast iron or bare steel. Through enhanced recovery mechanisms authorized by the New Hampshire Public Utilities Commission, that inventory has been trimmed approximately by 87%, to less than 47 miles, with one operator recently removing all remaining bare steel and cast iron in 2017 and another operator projected to remove all cast iron and bare steel by 2025. Presently, worn pipelines and leak-prone pipelines represent only 2.3% of the distribution mains in New Hampshire. More importantly, significant quantities of bare steel services that are directly connected to customers’ homes and businesses have been steadily replaced with the latest polyethylene pipelines. The Department of Energy Enforcement Division has been extensively involved with developing customized approaches applicable to New Hampshire gas distribution systems for determining which pipelines are subject to the highest pipeline safety risks. This requires, among other things, reviewing operators’ data integrity methodologies and algorithms used for weighting worn pipelines and determining priorities, requiring submission of physical samples, reporting on selected candidates for verification purposes, tracking associated expenses and incorporating replacements into inspection monitoring schedules.

Presently, four gas operator inspection units have either cast iron, bare steel or a combination of both remaining within their distributions. To address this potential safety risk, the New Hampshire Public Utilities Commission has implemented customized initiatives to spur replacement of this aged infrastructure. There are two programs in place for two of the three operators that are similar but structurally different. Despite the continued focus by the Enforcement Division, New Hampshire utilities, collectively, as of December 31,2021 ranked the 20th worst nationally in terms of percentage of pipelines containing cast iron and 40th worst in the nation in terms of percentage of pipelines containing bare steel.

Northern Utilities, Inc.

Northern Utilities Inc, within a settlement agreement approved by Commission Order 24,906 in DG 08-048, agreed to have all remaining bare steel mains in New Hampshire replaced by 2017. The Commission did not require an annual submittal of proposed mains, nor did it allow for surcharge recovery. There was no acceleration of bare steel replacement as it was deemed a continuation of the existing rate of replacement by predecessor companies but with a final date of replacement. It did not include cast iron mains of which Northern Utilities had a minimal amount remaining within its system.

Commission Order 25,563 in DG 13-086 allowed for two step adjustments to rates for eligible capital investments that were part a Targeted Infrastructure Rate Adjustment. Northern Utilities’ New Hampshire Replacement program was one of three eligible type infrastructure adjustments that could be made. The New Hampshire Replacement program was expanded to include cast iron mains as well as bare steel mains and costs of associated services. The initial step adjustment was included within the Order 25,563.

Commission Order 25,779 in DG 15-083 approved the second step adjustment to rates for the Targeted Infrastructure Related Improvements.

In 2017, Northern Utilities replaced the final segments of cast iron and bare steel mains thus new adjustments to the Targeted Infrastructure Rate Adjustment are no longer necessary.

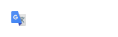

Northern Utilities NH Division Bare Steel Gas Services

From DOT annual reports - Chart showing reduction of bare steel gas services over time to zero in 2017.

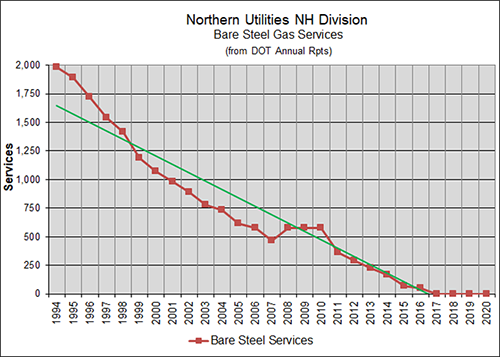

Northern Utilities NH Division Cast Iron Gas Main Replacements

Chart of Northern Utilities Annual Cast Iron Gas Main Replacements from DOT Annual Reports. 26 Miles of Cast Iron replaced since 1994. Zero remaining as of 2017.

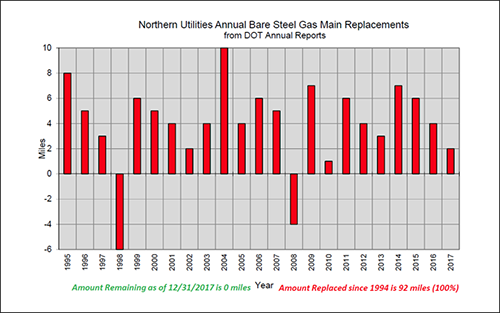

Northern Utilities NH Division Bare Steel Gas Main Replacements

Chart of Northern Utilities Annual Bare Steel Gas Main Replacements from DOT Annual Reports. 92 Miles of Cast Iron replaced since 1994. Zero remaining as of 2017.

EnergyNorth Natural Gas d/b/a Liberty Utilities

Commission Order 25,370 approved a settlement agreement in DG 11-040 that implemented a Cast Iron Bare Steel (CIBS) Replacement Program. This updated and replaced a former program that was initiated by Commission Order 24,777 in DG 06-107. Commission Order 26,374 in DG 20-049 was the final surcharge allowed and terminated the program effective calendar year 2020. The former program allowed for annual revision of rates for certain allowable capital expenditures associated with an annual replacement program of selected cast iron and bare steel pipeline segments within EnergyNorth’s gas distribution systems. The former program allowed for expedited recovery of four specific expenditures:

- unprotected bare steel main replacement, as determined by the evaluation and selection process;

- cast iron main replacement as determined by the evaluation and selection process;

- cast iron or bare steel main replacement candidates requested by field operating personnel; and

- bare steel services replaced as a result of a segment of bare steel main or cast iron main that is selected.

It also limited annual cost recovery to those above an indexed $500,000 threshold and deferred capital expenditures of associated work that was often performed during the replacement program. Eight items were specifically excluded from the CIBS rate adjustment but were eligible for cost recovery using traditional rate making procedures. They were:

- costs of moving inside meters to outside;

- costs of reconnecting existing plastic services or existing coated steel services from cast iron mains or bare steel mains to the newly installed replacement main;

- costs of any mains replaced made of polyethylene or steel having a protective coating;

- costs of any mains that were abandoned;

- costs of coated steel mains that “act as bare steel mains” such as poorly coated steel mains or disbonded steel mains, unless approved by the Enforcement Division;

- incremental costs of upsizing with the exception of low pressure 3-inch nominal diameter pipelines; and

- carryover costs in aggregate exceeding 5% of the approved estimated total expenditures under the CIBS program for the construction year, unless approved by the Enforcement Division. Such carryover costs included items such as restoration costs not incurred during the construction year.

- Replacements made under the Cast Iron Encroachment Policy were not eligible for accelerated rate recovery in the Cast Iron/Bare Steel Program unless a special circumstance was approved by the Enforcement Division.

Each construction season Liberty Utilities undertook an annual review of the performance of its distribution system as it related to the integrity of its cast iron and bare steel pipelines. This review provided: (1) a detailed analysis of leak activity over the preceding 10 years on the bare steel and cast-iron gas mains, and (2) an evaluation of which main segments represented the highest priority segments for replacement. Consideration was given to the age of the main, the date the leak(s) occurred, leak classification, type of leak, number of clamps used in leak repair, condition of main when repaired, specific leak location, building types in the area of the main segment and quantity of bare steel services attached to the potential segment to be replaced. Liberty Utilities was required to provide the Enforcement Division with actual cutouts of the worst section within any bare steel main segment replaced prior to reconciling any cost adjustments for associated construction season. Cutouts were required to be approximately 12 inches to 24 inches in length. They were also required to provide a written report accompanying the actual cutouts that includes: photographs the replaced bare steel segment; a general description of the condition of the pipe; the street address from which it was taken; age of material; original wall thickness; measured depth of deepest pit of the cutout; operating pressure of replaced pipe; pH of soil condition of cutout surrounds; results of testing for microbiological acid producing bacteria (APB) and sulfate reducing bacteria (colonies per ML); and identification of the threshold of high bacteria counts. Liberty bare steel segments removed to date is available.

Since 2009, EnergyNorth Natural Gas has replaced approximately 4,193 bare steel services and approximately 88 miles of leak-prone distribution main.

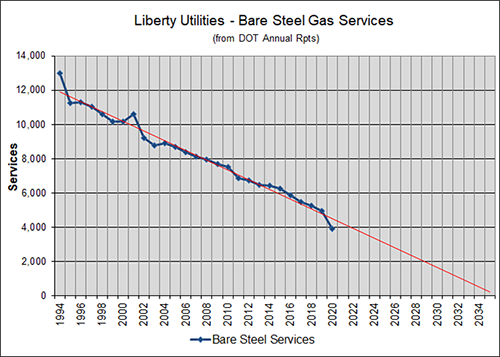

Liberty Utilities Bare Steel Gas Services

From DOT annual reports - Chart showing reduction of bare steel gas services over time.

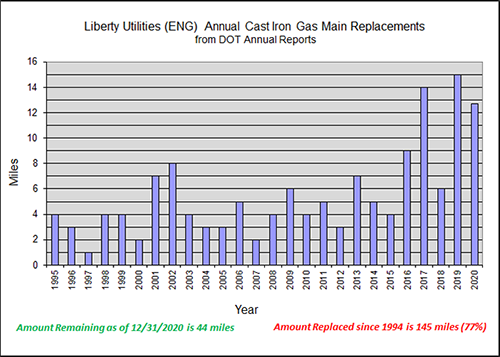

Liberty Utilities Cast Iron Gas Main Replacements

Chart of Liberty Utilities Annual Cast Iron Gas Main Replacements from DOT Annual Reports. 145 Miles of Cast Iron replaced since 1994. 44 miles remaining as of 2020.

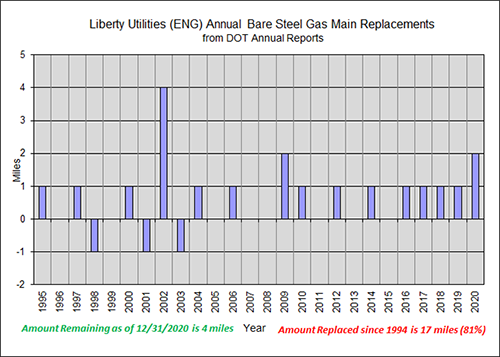

Liberty Utilities Bare Steel Gas Main Replacements

Chart of Liberty Utilities Annual Bare Steel Gas Main Replacements from DOT Annual Reports. 17 Miles of Cast Iron replaced since 1994. 4 remaining as of 2020.

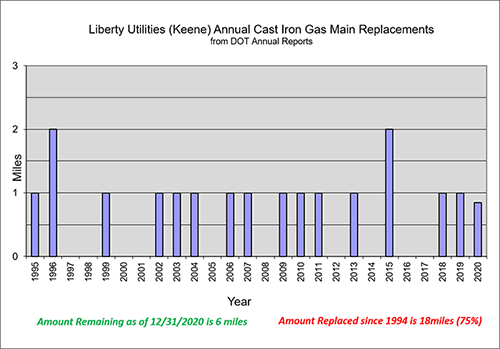

Keene Division of EnergyNorth Natural Gas Corp. d/b/a Liberty Utilities (formerly New Hampshire Gas)

There is no formal accelerated replacement program for Keene propane/air system. The leak prone piping consists solely of cast iron gas distribution mains as the system contains no bare steel mains or bare steel services. This division attempts to coordinate replacement projects with municipal work undertaken by the City of Keene.

Liberty Utilities - Keene Bare Steel Gas Main Replacements

Chart of Liberty Utilities - Keene Annual Bare Steel Gas Main Replacements from DOT Annual Reports. 18 Miles of Cast Iron replaced since 1994. 6 remaining as of 2020.